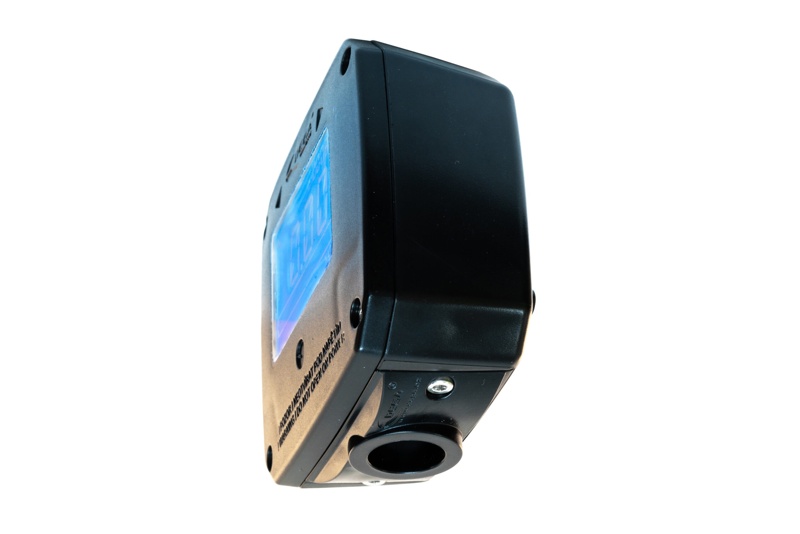

DEGA NB III LCD

Gas Detector

Applications

Designed for simple applications

Detection

Detection of toxic & explosive gases including oxygen

Protection

Protection IP 54, 24 VDC Power supply

Relays

2 x output relays

Basic gas detection methods:

CL – catalytic sensor (Pelistor)

They work on the principle of catalytic combustion – the gas concentration is measured based on the amount of heat released during the controlled combustion reaction. The reaction is supported by a suitable temperature and the presence of a catalyst. These sensors can be used to detect a wide range of flammable gases. The sensors are characterized by a fast response. They require at least 10% oxygen in the air for their proper function.

EL – electrochemical sensor

They work on the principle of changing the electrical parameters of the electrodes placed in the electrolyte as a result of the oxidation or reduction reaction of the detected gas on their surface. These sensors show good selectivity and ability to detect very low concentrations of toxic gases.

IL – infrared sensor

The highest quality sensing method. They work on the principle of infrared spectroscopy. The sensors have excellent selectivity for organic substances, do not need any oxygen content in the atmosphere for their operation and are resistant to catalytic poisons (sulphur and silicon compounds) that cause a change in the sensitivity of catalytic sensors. They are also characterized by great stability and a long service life.

SL – semiconductor sensor

They work on the principle of changing the electrical conductivity of the semiconductor when the concentration of the detected gas changes. The advantage is their long service life when working in a clean environment and a wide range for various types of gases and vapors. The disadvantage is low selectivity – the sensor reacts to a large extent even to gases for which it is not calibrated.

PID – photoionization sensor

A sensitive sensing method to detect a wide range of VOCs – volatile organic substances. The sensor non-selectively detects all VOCs in the air already at concentrations in ppm units.

| Power voltage | 8 – 30 VDC |

| Output | 4-20 mA, RS485, Modbus |

| Degree of protection by cover | IP 54, with DEGA WATER CAP IP 66 cover |

| Power consumption | 1,2 W |

| Dimensions | 150 x 170 x 65 mm (WxHxD) |

| Weight | 2,1 kg |

| Sensor type | catalytic, semiconductor, electrochemical, infrared, photoionization |

| Estimated sensor life in the transmitter in a clean environment | catalytic/semiconductor (1-2 years), electrochemical (1-3 years), infrared (5 years and more), photoionization (5000 hours) |

| Relative humidity of the surrounding air | 0-95 % RH |

| Location | BE3N2 – potentially explosive atmospheres, zone 1 |

Modules:

-

- DEGA NS III RS485 (Internal output RS485)

Accessories:

- DEGA NS III mechanical cover

- DEGA NS III stainless steel cover

- DEGA WATER CAP (splash guard)

- DEGA FUNNEL (funnel)

- DEGA GAS INLET (calibration attachment)

- DEGA NS III SU (replacement sensor unit)