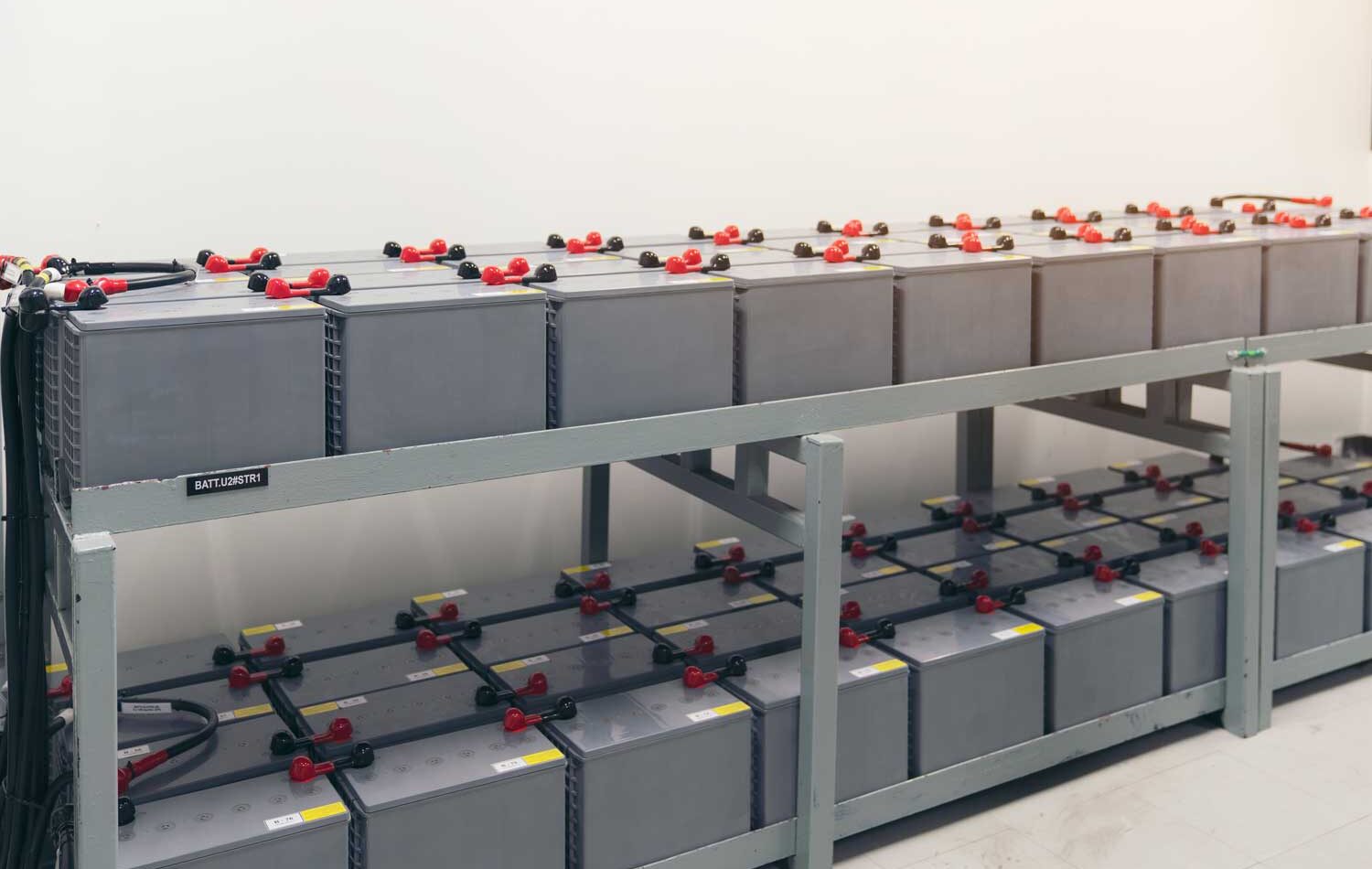

BATTERY ROOM MONITORING

Usually battery charging rooms and stations are designed to re-charge many lead acid batteries. Since a by-product of the charging process is Hydrogen (H), it is prudent to continuously monitor for dangerous levels of the H2 gas. Hydrogen becomes explosive at 4% VOL levels in air, so in enclosed areas this can be a concern to ensure that the charging system can be disabled and that necessary ventilation can be enabled.

Our battery room gas monitoring systems can identify issues with the charging process and also help to define what area of the room or station is problematic. As Hydrogen is lighter than air it is important to cover the top area of room or station, so that if a concentration of (H) was to rise, it is quickly identified by our transmitters and we can alert immediately that an explosive atmosphere is being created. We also have IECEx certification so you can be confident that we conform with all necessary legislation and regulations, so our sensors can be installed in Hazardous areas.

BATTERY ROOM AREAS MONITORED

- Battery Storage Areas

- Battery Charging Rooms

- Battery Charging Stations

- Forklift Battery Room

- Power Plant Battery Room

- Battery Shop

DATA LOGGING AND CONTROL PANELS

We also log and record all historical data to ensure full reportability to allow you to diagnose if a particular part of the charging process is at fault.

Control panels are also available that cover small 4 transmitter systems up to more sophisticated 250 transmitter systems. All our control panels have internal memory to retain alarm history for trend diagnosis. All our control panels and transmitters can be connected to audio/visual indicators such as sounders and beacons which can also supply as part of a solution.

LOCAL DISPLAYS AND OUTPUT CONNECTIONS FOR DATA INTERFACES

Our sensors can give a localised read at the sensor on our intuative LCD screen and we also provide multiple outputs to accommodate full system integration to your SCADA/DCS or alarm monitoring system. We can easily include our visual and audible indicators which are covered by our sounder / beacon range. We have all the major communication protocols such as digital, analog, serial, modbus and ethernet which can be connected to your new or existing site monitoring systems. We make sure that our systems monitor continuously through the battery bulk, absorption and float stages.